Mobile

+91-7906 830 840Office Location

Phoenix Chemicals B-21, Sarkhej Circle, Ahmedabad, Gujrat

Phoenix Chemicals B-21, Sarkhej Circle, Ahmedabad, Gujrat

Phoenix Chemicals since its inception has established a name for itself in the construction industry with a wide range of proven and time-tested products. With a special focus on quality, technology, and developing long-term relationships with clients, the organization has developed a track record of excellence.

Contact us

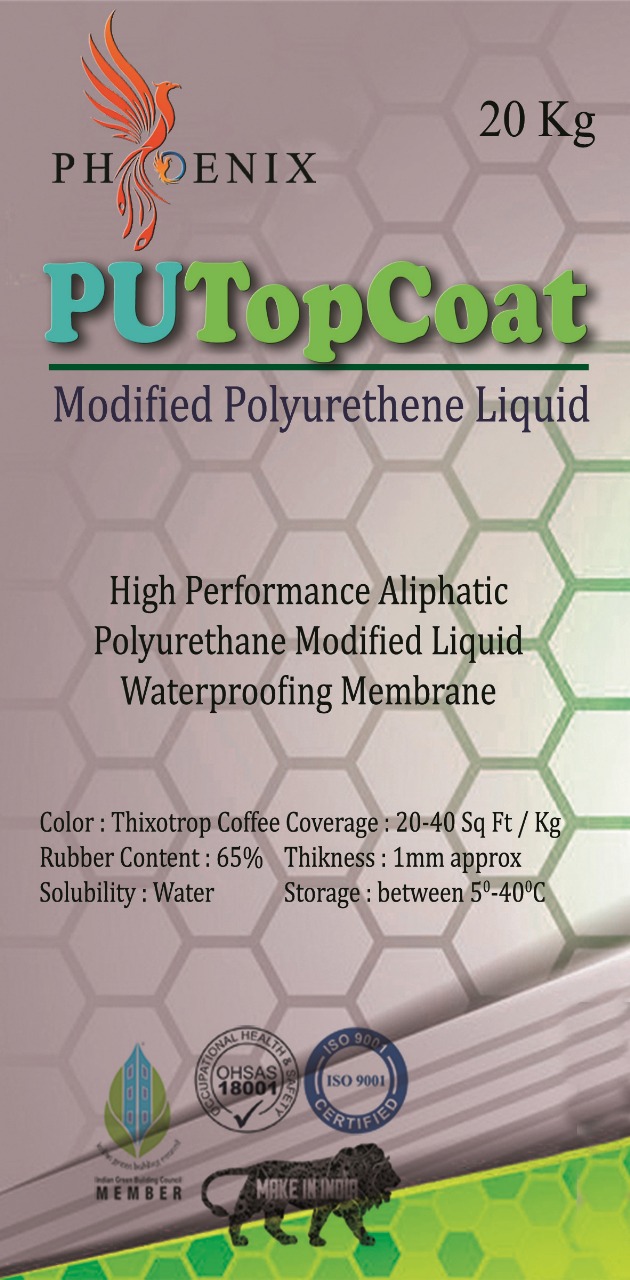

PU TopCoat is a high-performance, ready-to-use, cold-applied, single-component, elastomeric liquid waterproofing membrane based on aliphatic polyurethane modified bitumen emulsion. It forms a seamless, highly elastic, and durable film that adheres well to substrates like concrete, cement blocks, wood, and existing roof felts. PU TopCoat is highly resistant to chlorides and sulphates commonly found in soil and offers excellent UV resistance and long-term ageing stability.

| Sr. No. | Parameters | Specifications |

|---|---|---|

| 1 | Appearance | Thixotropic Black Emulsion |

| 2 | Rubber Content | 65% |

| 3 | Elongation (ASTM D412) | 900% |

| 4 | Tensile Strength (ASTM D 412) | 2 MPa |

| 5 | Specific Gravity | 1.2 |

| 6 | UV & Ozone Stability | Excellent |

| 7 | Temperature Resistance | -25°C to 100°C |

| 8 | Touch Dry | 2 – 3 Hours |

| 9 | pH Value | >9 |

All surfaces should be sound, clean, and free from contaminants. Absorbent surfaces like concrete should preferably be dampened with water. In kitchens, toilets, and other wet areas, all openings should be properly sealed, and weak points such as cracks or around pipes should be reinforced with woven fiberglass mesh between two coats of PU TopCoat.

PU TopCoat can be applied by brush, roller, or squeegee. Hot, dry, or very porous substrates should be dampened with clean water prior to application. When two or more coats are required, ensure the preceding coat is fully dry before applying the successive coat, which should be applied at a right angle to the previous coat. PU TopCoat can also act as a non-degradable curing membrane for concrete substructures immediately after mold removal.

Recommended thickness: 1.2 mm. For higher performance, apply glass fiber reinforcement between two coats of PU TopCoat.

Available in 20 kg containers.

Store away from direct sunlight under normal warehouse conditions in tightly closed containers. Shelf life is 12 months from the date of manufacture in unopened factory-packed drums.

Tools may be cleaned with water as long as the product is wet. Once dry, use mechanical means only.

Use rubber hand gloves, safety shoes, and safety goggles while handling. Avoid skin and eye contact. If contact occurs, wash with plenty of water and seek medical attention immediately.